- Home

- >

- Products

- >

- CNC Wire Saw Machine

- >

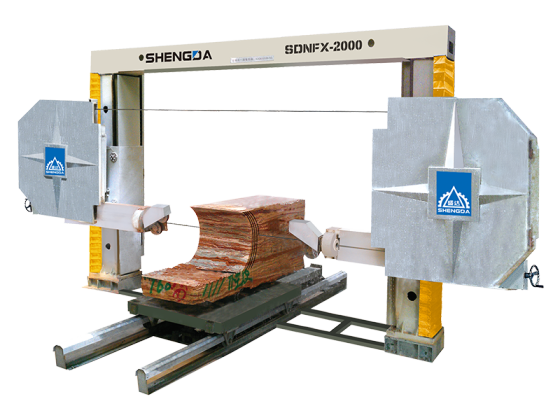

CNC Wire Saw Machine

This machine is an automatic, contouring machine, designed for carrying out complex architectural shapes such as profile, column slab, Roman column and words on granite, marble and every kind if natural stone.

CNC control and Windows XP interface make every preliminary and final operation simplified. It is able to be operated by telephone network in long range. The geometrical frame guarantees of absence of vibrations and an increasing of the wear resistance during time.

This machine according the CE standard, be provided with steady structure, including top bridge、empty column,V model slide guide, achieving the highest incise precision.

In ordering to reducing the diamond wear and tear, the machine equip two big flywheels (Diameter:1600mm) and two small flywheels (Diameter:500mm), one side flywheel install hydraulic pressure tense implement, it controls the wire rope tension or guide, at the same time estimate and maintain wire rope pressure. Another driving wheel install main motor, the motor equip transducer, it can control the speed of twice rope between 0-40m/s, the machine can use in all different kind of stone material.

- Information

- Video

1、Four guide wheel (Diameter: 240mm)

2、Area of the incision have the special cooling water system

3、Control panel: including servocontrol system and CNC numerical control

4、CNC numerical guide wheel and trolley, fluctuate linkage guarantee the wire rope exact cutting orientation

At the PC control panel, operator can via keyboard, carry through programme and enactment cutting parameter. Contemporary can achieve lots of other applied cutting manipulate, for example: in the process of cutting, accelerate or require high precision, via enact the line form achieve the cutting speed by electromotor control.

Both side double tense system increase the cutting speed and precision.

Circumgyrate speed stepless shift gears can avoid he machine feasibility librate and safe equipment, reaching the best capability.

Via program system automatic cutting slab, enacting blade cutting number and the slab thickness.

Cutting can reach automatism: trolley structure including four special backstop, avoiding slab move and approach the wire rope.