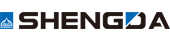

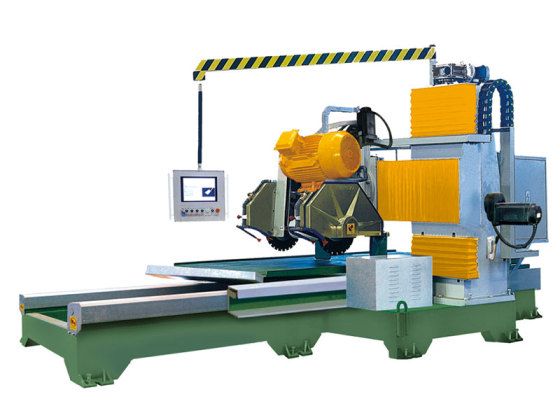

Three-axis CNC Line Machine

1, Tool rest left and right moving axis (X), beam moving axis (Y) using straight track and high-precision helical gear transmission, tool rest lifting axis (Z) using straight track and ball screw transmission, to provide a guarantee for the machining accuracy of the machine tool.

2, The moving beam structure changes the traditional workbench movement mode, greatly improve the Y axis movement speed, greatly improve the processing speed.

3, The independent workbench, ensure the convenience of loading and unloading, workbench height is more suitable for ergonomic design concept, so that the operator is convenient and fast.

4, The design of double knife widening and super wide working table, so that the machine can simultaneously process two pieces of 800mm wide working piece, adapt to a variety of customer choices.

- Information

- Video

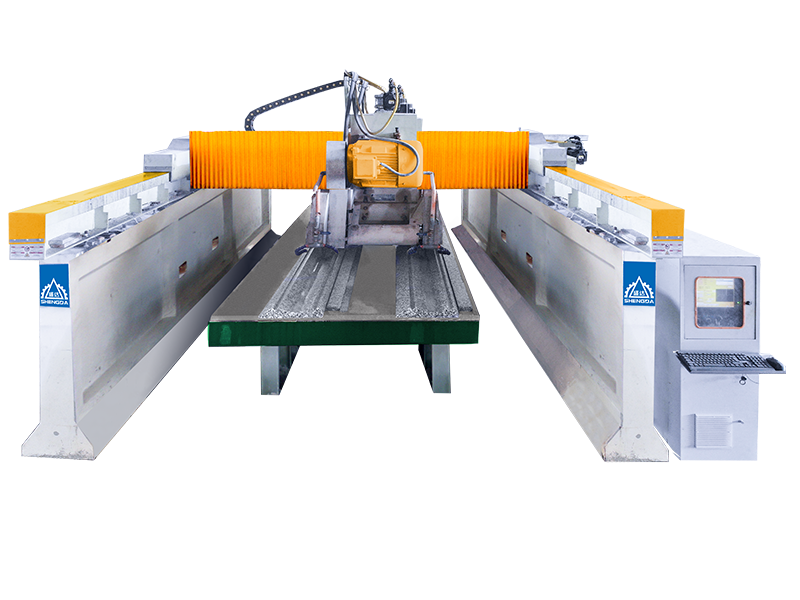

System control architecture:

1. The new generation of bridge CNC line machine adopts a self-developed CNC system mounted on the traditional Windows computer system. In order to adapt to the harsh industrial environment, it adopts a fanless and low-power industrial computer. The CNC module uses EtherCat fieldbus to communicate with the servo system. The communication speed is fast, safe and reliable, which ensures the safety and reliability of the machine.

2. The servo system uses Delta A2 high-performance series products, which features EtherCat bus driver of absolute value encoder to ensure the precision of machine position.

3, closed electrical control cabinet design, to ensure that electrical components in the harsh environment is not easy to damage.

4, the design of the remote control, throw away the traditional suspension rod, knife is always more convenient and fast.